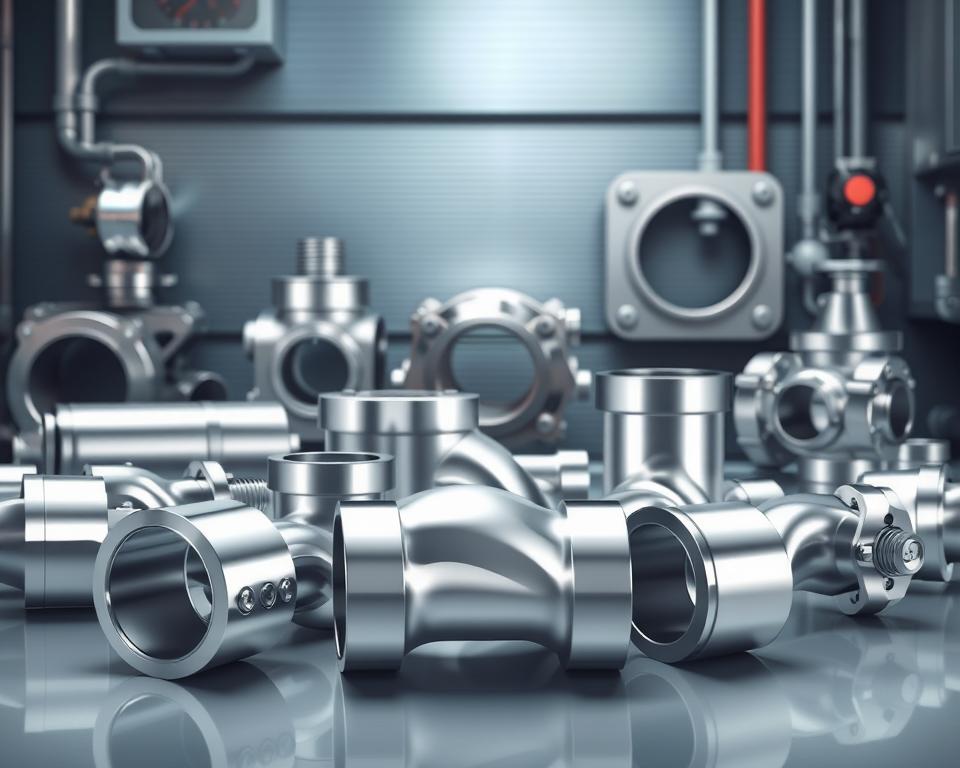

Premium Tri-Clamp Hygienic Couplings for Hygiene

In industries where contamination can be fatal, even micro-fissures pose a risk. Hence, companies like Installation Parts Supply offer expertly engineered solutions built to remove hazards. Such hygienic connection systems couple long-lasting strength with seamless assembly, rendering them a top choice for operations that insist on flawless results.

These fittings go beyond merely sealing fluids – they’re intended to surpass the demanding requirements of food manufacture, brew operations, and pharma operations. Manufactured using chemical-resistant stainless, they survive ongoing sanitizations while maintaining structural integrity. The engineering ethos echoes industry leaders like Alfa Laval, placing first sanitary coupling smooth surfaces and quick disassembly.

What distinguishes these items? Think single-handed setup and tool-less upkeep. Operators enjoy the straightforward build during busy shifts, while managers prioritize reliable operation across pipelines. Every piece faces rigorous inspections to confirm conformity to FDA and 3-A Sanitary Standards.

Major Findings

- Trusted by professionals for drip-free sealing in sensitive settings

- Built using food-grade stainless steel for lasting durability

- Simplifies compliance with food safety and pharmaceutical guidelines

- Cuts stoppage through snap-lock construction and scrub-down

- Backed by quality assurance protocols matching global benchmarks

Product Overview and Key Benefits

Leak-free unions are the backbone of hygienic processes. Installation Parts Supply engineers components that marry fine-tuned tolerances with real-world usability. Their systems grant hermetic sealing while streamlining service routines—critical for markets where quick production meets sanitation.

Elite Grade & Hygiene Compliance

Every piece is heavily tested to meet global benchmarks. The metals fight rust and pockmarks, even after constant cleaning rounds. Seamless seals block pathogen buildup, a feature praised by dairy processors and pharmaceutical manufacturers alike.

These fittings emulate the standards of leaders like Alfa Laval, guaranteeing smooth surfaces and uniform dimensions. Flexible configurations adapt to existing setups, minimizing conversion fees. Line staff note 30% swifter builds compared to traditional threaded systems.

Why Choose This Supplier

Made-to-order builds sets this supplier apart. Looking for unusual geometry or rare plating? Their team collaborates directly with clients to produce precise builds. Express delivery and 24/7 technical support prevent bottlenecks.

The gains go past toughness. Snap-apart removal cuts downtime during microbial reviews. Beverage plants using these connectors record fewer production stoppages and uniform pressure. It’s not just about hitting the rules—it’s about going beyond without strain.

Specs & Architectural Features

High-accuracy design marries versatility in contemporary production lines. Installation Parts Supply builds components that harmonize precise dimensions with customizable setups. Their strategy guarantees easy incorporation into running equipment while keeping strict hygiene protocols.

Bespoke Metals & Finishes

No two projects are identical. That’s why grades available run 304 to 316L, preferred for strength and corrosion resistance. Surface treatments like electro-buffing generate mirror-like smoothness, cutting microbial stickiness by up to 40% compared to standard finishes.

| Finish Type | Key Feature | Compliance |

|---|---|---|

| Electropolished | Ultra-smooth surface | ASME 3A, ISO 9001 |

| Mechanically Polished | Cost-effective shine | 3-A Sanitary Standards |

| Bead-Blasted | Non-reflective texture | FDA Food Code |

Manufacturing processes deploy laser measurement tools to guarantee uniform wall thickness. Precision limits (±0.005″) stop stress points in pressure-heavy systems. During quality checks, components experience X-ray scans and pressure tests to spot microscopic flaws.

Tailoring goes past appearance. Clients request unique bends, flange sizes, or dedicated coatings for chemical resistance. These bespoke solutions help industries comply with new rules without tearing out full lines.

Tri-Clamp Fittings – Setup & Uses

Today’s fast-paced facilities call for units that set up swiftly yet perform reliably. These coupling sets excel in environments where rapidity intersects sterility. Their design scraps complicated hardware, permitting teams to stay productive rather than fitment hassles.

Streamlined Setup Procedure

A pair of flanges and a centered gasket create perfect seals in seconds. Operators place the parts, insert the squeeze band, and hand-tighten – no wrenches required. This method diminishes mounting blunders while ensuring uniform force across the joint.

| Step | Traditional Method | Modern Solution |

|---|---|---|

| Alignment | Thread matching required | Flanged ends self-center |

| Sealing | Multiple tape layers | Single food-grade gasket |

| Securing | Torque wrench needed | Hand-tightened mechanism |

Convertible Connections for Gear

From stainless steel tubes to processing equipment, these interfaces link unlike gear seamlessly. The uniform design mates to various diameters, enabling fast changeovers during product changeovers. Dairy plants often use them to switch between cleaning cycles and production runs seamlessly.

Sanitation staff like how components come apart for thorough sanitation. Smooth surfaces halt grime collection, while the smooth bore removes crevice dangers. Weekly cleanings run in half the duration compared to older connection methods.

Industry Applications and Compliance Standards

Covering brewpubs to immunization facilities, modern facilities trust in fittings that adapt to diverse needs while conforming to tight guidelines. Installation Parts Supply supplies solutions used across vital fields where product purity must be absolute. Their designs bridge operational efficiency with regulatory demands, forging setups that work under strain.

F&B plus Pharma Fields

In food and beverage plants, swift-change clamps streamline hopping from batch to CIP. Breweries deploy specific T-joints to manage complex flow paths while eliminating cross-mix hazards. Pharmaceutical manufacturers rely on airtight seals to guard delicate ingredients during sterile transfers.

These fittings are available in varied dimensions to match piping layouts, from micro facilities to industrial vats. Dairy processors value how standardized parts diminish breaks during equipment upgrades. Even tiny alterations in production processes are managed through modular designs.

Compliance with ASME/ISO/3-A

Every product achieves and goes beyond benchmarks set by global organizations. ASME-certified materials manage hot media in pasteurization systems, while ISO-compliant finishes deny biofilm. The 3-A symbol guarantees suitability for direct contact with consumables.

Tri-Clamp unions embody this pledge. Their uniform dimensions deliver impermeable results across automated lines. Third-party audits verify traceability from raw materials to finished goods, providing inspectors certainty.

By conforming to these rules, facilities streamline certification processes and earn approvals quickly. It’s not just about avoiding fines—it’s about earning client confidence through demonstrable safety practices.

Summary & Suggested Actions

Choosing components that balance performance and compliance guides plant achievements. Installation Parts Supply brings systems combining durability with hygienic design, providing leak-free performance across food, pharma, and beverage environments. Their products surpass rigorous standards while easing everyday operations through intuitive assembly.

With variants in steels and textures, solutions tailor to distinct facility goals. Whether carrying thermal streams or endless sanitation loops, material choices and surface treatments boost endurance. Professionals praise the wide selection of connection types tailored to set velocity and line pressure.

Procurement stays smooth, with pro advice waiting to fit plant specs. Rapid dispatch and responsive service slash outage risk during upgrades or replacements. Periodic cleaning becomes effortless thanks to no-tool breakdown and slick interiors that fight fouling.

Looking to improve operational trust? Speak with Installation Parts Supply to explore tailored configurations – from tri-clamp-style to sanitary tri-clover links – supported by top-tier QA. Their team confirms present-day adherence while readying plants for future regs.